How to Prevent Common Paint Defects: A Troubleshooting Guide for Manufacturers

- Vikas Nadkarni

- Aug 9, 2025

- 4 min read

Paint manufacturing is a complex process that requires precision, expertise, and the right balance of raw materials. Even a minor miscalculation can lead to defects that compromise the paint's performance and durability. Whether you are an established manufacturer or a startup, understanding how to prevent common paint defects can save you from costly product failures and customer dissatisfaction.

In this troubleshooting guide, we will address three frequent issues—flaking, settling, and bubbling—along with actionable solutions to maintain the quality of your paint formulations.

1. Flaking: The Silent Enemy of Paint Adhesion

What Causes Flaking?

Flaking occurs when paint loses adhesion and peels off the substrate. This is often due to an incorrect binder-to-pigment ratio, poor surface preparation, or environmental factors like extreme temperatures and humidity. Insufficient curing time or excessive dilution with solvents can also contribute to this defect.

How to Prevent Flaking

Optimize the Binder-to-Pigment Ratio: The binder-to-pigment ratio varies based on the type of paint and its intended application. However, an industry-standard ratio for architectural coatings is typically 1:2 to 1:4 (binder to pigment by weight). The absolute minimum ratio should not fall below 1:5, as a lower binder content may lead to weak film formation and flaking. For industrial coatings, this ratio can be different depending on resin types and performance requirements.

Surface Preparation: Clean and prime the surface properly before application to remove dust, grease, or moisture that can weaken adhesion. Mechanical abrasion can enhance bonding.

Use High-Quality Resins: Selecting the right resins with strong adhesive properties can enhance durability and prevent flaking e.g., styrene-acrylic or pure acrylic) provide superior adhesion, flexibility, and resistance to environmental conditions.

Control Curing Conditions: Ensure proper curing times and environmental conditions to allow the paint to form a strong film. e.g., Water-based acrylic paints: 24-48 hours for full cure. Solvent-based epoxy coatings: 5-7 days at room temperature (faster with heat curing).

Conduct Adhesion Tests: Perform cross-hatch adhesion tests to evaluate the paint’s ability to adhere under different conditions.

2. Settling: The Downfall of Paint Consistency

What Causes Settling?

Settling occurs when pigments and fillers sink to the bottom of the container over time, leading to inconsistent color and texture. This issue is primarily caused by low viscosity, improper dispersion, or inadequate use of stabilizers. Environmental factors such as prolonged storage at high temperatures can exacerbate the problem.

How to Prevent Settling

Use Anti-Settling Agents: Add rheology modifiers or thixotropic agents to improve pigment suspension and prevent hard sedimentation e.g., fumed silica (Aerosil 200), organoclays (Bentone 38, Tixogel VP), or polyurethanes (Acrysol RM-825) to increase viscosity and prevent hard sedimentation. Use cellulose ethers (Natrosol 250) for water-based paints and castor oil derivatives (Thixatrol ST) for solvent-based formulations.

Optimize Viscosity: Maintain a balanced Pigment Volume Concentration (PVC) below the Critical Pigment Volume Concentration (CPVC) to prevent excessive settling.

Adjust solvent balance with butyl glycol, white spirit, or Texanol to ensure proper flow and prevent hard settling.

Employ High-Shear Mixing: Proper dispersion techniques, such as high-speed mixing or bead milling, can prevent particle aggregation and settling. Use high-speed dispersers or bead mills to break down pigment aggregates. Pre-disperse with wetting agents to enhance stability before full mixing.

Regularly Test Stability: Conduct heat stability tests (store at 50°C for 7 days) to assess settling behavior. Perform centrifuge tests (3000 RPM for 10 minutes, ASTM D 1200-10) to predict long-term storage stability. Use Grindometer (Hegman gauge test) to measure dispersion quality.

Use Proper Storage Conditions: Store paint in moisture-free, sealed HDPE or metal containers to prevent solvent evaporation. Maintain storage between 15°C to 30°C to avoid thickening or destabilization. Stir bulk containers every 3 to 4 weeks to prevent heavy fillers like barium sulfate or calcium carbonate from settling.

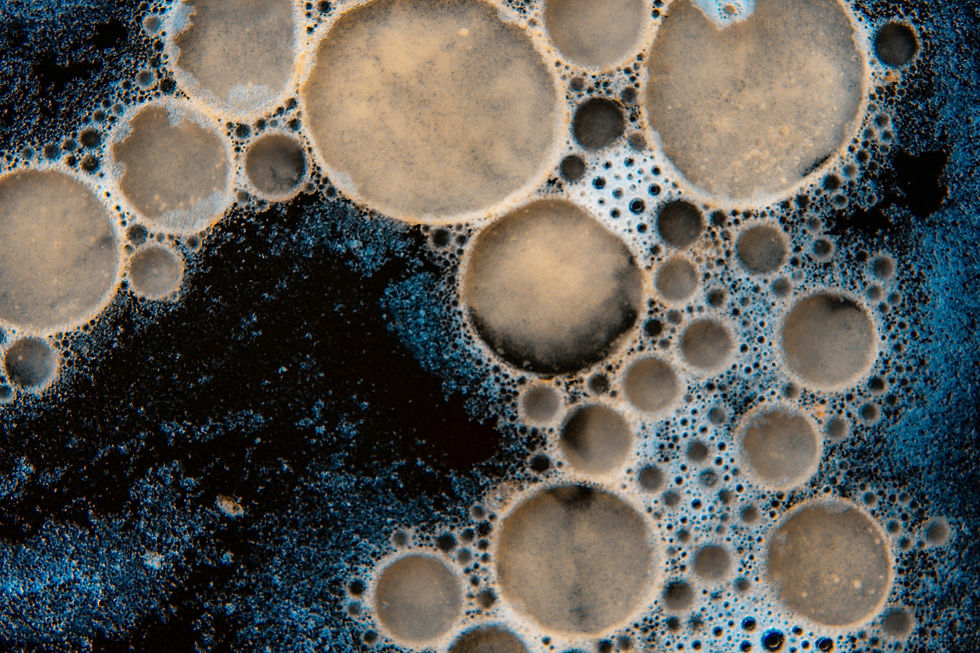

3. Bubbling: The Invisible Trap for Paint Quality

What Causes Bubbling?

Bubbling occurs when trapped air or solvent vapors expand and create voids in the paint film. This is often due to high-speed mixing, excessive solvent evaporation, or improper application techniques. High humidity and rapid drying conditions can also contribute to bubbling by trapping moisture within the coating.

How to Prevent Bubbling

Incorporate Defoamers: Use silicone-based defoamers for solvent-based paints. For water-based formulations, incorporate mineral oil defoamers or polyether-modified siloxanes to break foam efficiently. Add defoamers at 0.1-0.5% concentration during pigment grinding or final letdown.

Adjust Mixing Speed: Avoid excessive turbulence by keeping blade tip speeds below 20 m/s when using a high-speed disperser (Cowles blade system). Use vacuum mixers for air-sensitive formulations. Ensure pigment wetting with Disperbyk-110 or Solsperse 20000 to reduce air entrapment.

Control Solvent Evaporation: Avoid excessive fast-evaporating solvents like acetone and MEK in warm conditions. Adjust drying rate with Texanol or Glycol Ether to promote uniform film formation. Use slow-evaporating coalescents (Eastman Optifilm Enhancer 400, BYK-3456) to minimize bubble entrapment.

Apply in Thin Layers: Use a wet film thickness gauge to ensure application does not exceed 100-125 microns per coat. For industrial coatings, apply with HVLP or airless spray systems (Graco UltraMax II) to minimize trapped air. Utilize leveling agents (Byk-358 N, EFKA-3777) to ensure a smooth finish.

Ensure Proper Ventilation: Maintain airflow rates of 0.3-0.5 m/s in application booths to control solvent release. Use forced-air ovens (Despatch LCC, Weiss Technik Airflow 450) for controlled drying. For water-based paints, avoid high-humidity environments above 75% RH to prevent moisture entrapment in the film.

Conclusion

Preventing paint defects requires a deep understanding of formulation chemistry and process optimization. By addressing these common issues—flaking, settling, and bubbling—you can significantly enhance product quality, reduce wastage, and ensure customer satisfaction.

Need Help with Your Paint Formulations?

Reach out to our experts at Arcane Chemtech for customized solutions and cutting-edge paint technology that gives your products a competitive edge.

Comments